This article provides an overview and analysis of Masking costs, common masking methods, and introduces a new solution: UV Curable Masking Resins. The article looks closely at the benefits and advantages of UV Masking Resins.

Masking for Surface Finishing

Masking presents unique challenges within a variety of industries, including medical devices. Components are expensive, of high precision and subject to strict standards of manufacturing to avoid contamination. In today’s environment, quality and cost go hand-in-hand. Masking can add significant cost, decrease throughput and cause defects requiring rework or scrapping.

Cost of Masking

Masking of components and surfaces is a necessary part of every finishing process. Whether for grinding, abrasive cleaning such as grit blasting or vibratory finishing, acid stripping, shot peening, anodizing, chemical milling, plasma spray or plating, masks act as a self-sacrificing barrier for surface preparation. The more complex and intricate a component, the longer it takes to apply and remove traditional masks such as tapes, waxes and solvent based lacquers.

The costs associated with masking may not be readily apparent, as the masking material itself is typically not the major contributing element to overall cost. The major cost derives from the masking process itself. Additional costs include: labor to apply and remove the masking, scrap components, component reworking, production bottlenecks, elapsed time, floor space, waste disposal and OSHA and EPA compliance for solvent-based masks.

When all cost elements are considered, the process with a lower labor component and lower defects in the winner. If one only considers the lowest cost masking material, the lowest total cost is rarely achieved.

Masking Methods

The most popular products used in most masking applications include tapes, lacquers, waxes and reusable boots and plugs.

Tapes

Masking tapes range in composition for the simple, low-cost paper tapes typically associated with painting, to expensive, heat-resistant polyester, poly-amide and silicone used in high temperature surface finishing. Tapes are dispensed from a roll and are cut to fit the area to be masked. Some can be purchased in die-cut shapes, but this can be costly and is usually limited to high volume production of a single component configuration.

Masking with tape is perhaps the most labor-intensive masking process, especially for complex surfaces. However, if the geometry is simple and tape holds up to the process, taping can be effective and low cost. Tapes are applied by hand, and in most instances of multiple surface processing operations, are re-applied in the same areas due to abrasion and wear. It is not uncommon for an operator to spend two to four hours masking a single intricate component.

In addition to being time consuming for difficult geometries, the taping process can also pose dangers for employees. Despite the best protection, employees can sustain finger cuts from razor blades and from the tape itself.

Boots, Caps & Permanent Masks

Boots and molded caps, typically made of rubber or vinyl, are used in high-volume processing of components with no dimensional variations. Because the cost of molds can be quite high, it is cost prohibitive to have boots and caps molded for small volumes, or for components with varying configurations or dimensions. Thus, molded boots and caps are not suitable as a universal masking media. Rather, they are product-specific. For long runs, where they fit well, boots and caps are a cost effective method.

Boots and caps rely on press-fit tolerances and elasticity to affix themselves to the components. However, this is not adequate protection for liquid processes such as acid cleaning and plating. Boots and caps will eventually wear out after repeated use. They can also loosen and fall off during the process, creating costly rework or scrap.

Permanent masks may also serve as fixtures to hold the part during the finishing operation. Because of their high engineering and design costs, they are only suited for long runs. Also, for applications such as plating, where a very tight fit is required, they may not afford the required quality.

Lacquers

Typical masking lacquers are solvent-based and require a prescribed curing time to allow the solvent to evaporate and for the remaining resin to cure or harden on the components. This type of curing process requires that masked components be stacked or racked and left undisturbed for a period of time ranging from several minutes to several hours. Not only is the process bottle-necked, but valuable production space is consumed with curing parts.

Lacquers are used because the material cost is low and because they may stand up to plating and milling chemicals. However, the total cost of using these masks is high for the following reasons.The solvents contained in many lacquers are the same solvents that are being restricted or banned in the workplace by governmental agencies for health and safety concerns. In addition, solvents can be extremely flammable, posing other health and safety risks. Solvents, and products containing solvents, must be carefully monitored in the work environment.

Lacquers are predominantly watery, low-viscosity products. In order to provide adequate protection as a mask, it may be necessary to repeat the dispense and cure cycle several times to build the proper mask thickness. Multiple masking cycles create delay and cost. Finally, lacquer removal can be difficult. Typically, lacquer-masked components are first warmed, then soaked in a solvent such as acetone. Solvent-based masks are generally a last resort for use in situations where they represent the only workable masking solution.

Waxes

Wax is perhaps the least expensive material that can be used for masking. However, it is difficult to work with, as it must be heated above its melting point to apply (150° F or higher). Heating requires special handling equipment and thermal energy, which can thus generate a surprisingly high utility cost. Typically, wax is poured into components to protect the internal cavities. Parts with tight dimensions and serpentine pattern cavities must be pre-heated to allow proper flow or wax. Dipping is the only practical method of coating external surfaces, because hot wax cannot otherwise be applied in a controlled fashion.

Removal of wax requires the same melting process as the application of wax, with the exception that the component must now be heated with the wax. Wax removal is usually conducted in a hot water bath. Care must be taken to ensure that all wax is removed from components, and the water bath must be well filtered or replaced frequently to keep the water clean. An additional cleaning operation is often required after wax removal.

A New Option: UV Curable Masking Technology

Most companies contact us because they are experiencing quality, rework or scrap problems with their current masking approach, or because of a concern about high labor hours. A new technology to address all of their concerns is now available with the use of ultraviolet (UV) Curable Masking Resins.

Worker-friendly and OSHA compliant, UV Curable Masks are solvent-free, low odor, non-flammable liquid resins that cure in seconds upon exposure to ultraviolet light energy. They are specifically formulated to have no effect on the metallurgical characteristics of the surface being masked. These resins are urethane-based and contain no heavy metals, silica or other compounds that can alter the properties of the component surface or the finish being applied. Once cured, these resins can be handled like any industrial plastic. When removed by recommended methods, UV Curable Masking Resins leave no residue.

These resins are single-component formulations that eliminate the need to measure and mix prior to using. UV Curable Masks are available in a variety of containers to accommodate any dispensing system, ranging from small syringes to bulk packaging measured by weight or volume.

UV Curing Systems

Critical to the UV mask curing process is an ultraviolet light energy source. Several types of UV curing lamps and systems are available. Spectral output of the lamp, intensity, component configuration, desired production throughput and budget are all factors that help determine which type of UV curing system is appropriate.

UV lamps may be grouped into two broad categories. UV spot lamps generate high intensity UV energy that is directed through a fiber or liquid filled light guide, typically 5-8 mm in diameter. Flood lamps can be used which create light footprints up to 8″ square. Systems are also available that combine curing lamps with dispensers or conveyors for semi-automated production. This permits continuous in-line processing of components with no delays.

UV Curable Masking Resin Types

There are two basic grades of UV Masking Resins: Peelable and Burn-Off.

Peelable Masking Resins

Perhaps the most versatile of UV Masking Resins, the peelable grades provide good adhesion to most clean metal surfaces, are resilient enough to withstand a variety of surface treatment processes and can be removed through a simple peeling process. Cured in a few seconds with UV Light, peelable masks have been successfully qualified for surface protection in processes such as grit blasting, shot peening, acid cleaning, plating and anodized coatings. The surface bond is very strong and durable, possessing sufficient adhesion to survive through multiple surface cleaning and processing operations, eliminating the need to strip and re-mask between processes. Peelable UV Masking Resins offer uniform adhesion from edge to edge, preventing processing media from creeping underneath.

Peelable UV masks are easily removed by lifting up an edge manually or with the help of a non-abrasive tool, then pulling.The elasticity of of the material typically permits fast removal of the mask in one piece rather than in fractured segments. No residues remain on the surface after the mask is removed. The peeling process is made even easier by warming the cured masking resin to 120°-150° F in a warm water bath or oven, or by using a localized heating element. The peeled material, essentially a plastic resin, is non-hazardous and may be disposed of in accordance with local regulations for industrial scrap plastic.

Burn-Off Resins

These grades typically offer the best surface adhesion and provide the greatest resistance to heat and aggressive chemical solutions such as acid / alkali baths. Heat curable grades can be used for core cavity sealing to protect from debris, plating baths, and laser burn-through during drilling operations. Surface curing with UV light may take 20-30 seconds under a flood lamp. The removal process for a burn-off grade mask requires that components be baked in an air-enriched furnace at temperatures between 900° – 1400° F. Complete burn-off can be achieved in as little as 15 minutes for thinly coated surfaces. For core cavities, cooling holes or thick mask coatings, a bake cycle of one hour or slightly longer may be required. Burn-off masks are limited to parts that can tolerate high heat.

In many instances, an existing heat treating operation may also be used to burn-off the mask. The burn-off process effectively incinerates the mask and leaves no residue on the component surface. The composition of the UV Curable Mask allows it to completely combust and be exhausted from the furnace. And, the metallurgy of the heat-treated component remains unaffected by the UV Curable Masking Resin.

Medical Device Applications

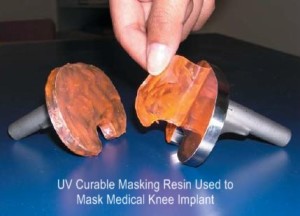

The photo above shows the utility of UV Curable Masking applied to knee tibial components. Generally speaking, the posterior aspect of the implant (the side that eventually mates with the bone) is roughly textured. Some manufacturers “grit blast” this surface with aluminum oxide – an extremely aggressive blast media. During the blasting process, the anterior aspect of the implant (which will be highly polished) must be protected. In this instance, UV curable Masking Resin is used in its peelable form. It is then cured under a UV lamp for less than one minute. The blasting is performed, and then the mask is warmed in a sonic bath or with a heat gun and the mask peels off easily by hand. There is no residue, and the curing can be conveyorized.

UV Masking Advantages

Major advantages include:

- Process lends itself to automation

- Short runs also lend themselves to significant savings

- Labor can be reduced significantly

- Scrap and rework can be reduced or eliminated

- Environmentally friendly

UV Curable Masking Resins are versatile in the finishing of medical devices, such as hip or knee components, as well as surgical instruments. UV Masking Resins provide significant improvements in performance compared to other masking solutions available. Cost reduction and enhanced productivity are primary drivers in the pursuit of new applications for use.