An effective method for stripping all metal types, plastic media blasting removes all or a portion of a cured powder coating from the surface of a part without causing damage. This article defines plastic media blasting and compares it to several other stripping methods used in powder coating. The article also discusses the environmental advantages of plastic media blasting, the types of plastic media and blasting equipment available, and the cost of operating a plastic media blasting system. Many application examples are included.

The advent of powder coatings has been both a blessing and a curse to the manufacturers of many commercial and industrial components. Although powder coatings have solved many coating problems and produced incredibly durable finishes, they can be difficult and costly to remove when a part needs re-coating. Several stripping methods are used to remove powder coatings from parts, including the following:

Molten salt. This method involves dipping the part to be stripped into a pot of molten salt. The salt is kept in a liquid, or molten, state at temperatures that turn the powder coating to ash and vapor.

Burn-off oven. This method works essentially like the molten-salt method, except the part is put into an oven instead of a pot. The oven is kept at a temperature that turns the coating to ash (usually between 600 F and 900 F).

Glass bead blasting. This method involves the use of small glass beads in an abrasive blast process to remove a powder coating or to impart a non-directional finish, or texture. When used to remove powder coatings from relatively soft substrates, such as aluminum, this method can produce unsatisfactory part appearance or performance from the surface stress and texture left by the impacting beads.

Many substrates currently coated with powder can’t survive the coating removal process, or if they do, their structural properties are significantly diminished because of the extreme heat used to remove the coating. Fortunately, there is an alternative — plastic media blasting (PMB). Using recyclable plastic media, PMB removes powder coatings while generating only a small amount of dry residue. The plastic media are nonhazardous; therefore, if the powder itself doesn’t pose an environmental problem, hazardous waste is nonexistent.

Applications for Plastic Media Blasting

PMB technology has been in use since the 1980’s, principally for stripping aircraft and aerospace components. The technology was fostered by the US Department of Defense to replace the toxic chemical strippers previously used on strategic military aircraft and aerospace parts.

The US EPA’s final rule prohibiting the disposal of certain chemical solvents in landfills throughout the country, including the most effective chemical strippers containing methylene chloride and phenols, stimulated the use of PMB. An alternative disposal method — incineration — can cost up to $1,000 for a 55-gallon drum of these chemical effluents.

Because the plastic particles used in PMB are harder than the coatings but softer than the substrates underneath, they can quickly remove primers and topcoats without harming the substrate, especially substrates sensitive to deformation, such as aluminum alloy.

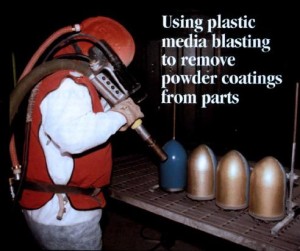

For example, since 1989, PMB has been used to strip a particularly tough epoxy coating from aluminum alloy bobbins that hold missile guidance wires (see photo above). The soft plastic media don’t affect the aluminum alloy or the very fine wires that cna be rejected for even microscopic surface irregularities. Before plastic media blasting use in 1989, rejected bobbins were scrapped.

The aluminum missile airframe shown above is another example of a part that is suitable for plastic media blasting. In its assembled state, the airframe is impossible to strip using heat or hard abrasives. Although hand sanding is possible, it removes the chemical conversion coating, which can’t be replaced economically to the assembled airframe. The plastic media remove the powder coating from the cracks, crevices, and rivet heads without damaging the substrate or removing the conversion coating.

Another example of the effectiveness of plastic media blasting involves a sophisticated naval torpedo casing shown here. The casing requires a stripping method that removes the powder coating and leaves the aluminum conversion coating intact. Chemical strippers are ineffective. They also don’t lend themselves to the semi-assembled configuration of the casing, which includes various fasteners and inserts that can be damaged by the chemicals. The casings are also on a very tight delivery schedule. As a result, the casing is sent on an aircraft to a company that does plastic media blasting and sent back the same day.

With more environmental awareness and stricter environmental regulations in the coatings industry, PMB has matured into a technology suitable for a broad range of applications, including aluminum alloy wheels seen here.

Pot metal castings and the intricate cast-in artwork on them also are completely cleaned, which leaves contamination-free surfaces for re-coating. for example, a set of cast-aluminum patio furniture requires stripping before powder coating. The original coating is resistant to chemical stripper, and the hours of hand cleaning required would be expensive. Hard-abrasive blasting would excessively profile the surface, requiring the use of a sanding primer. The design detail in the casting would also require a great deal of hand sanding. With PMB, the old coating is quickly removed and the casting detail is effectively cleaned without leaving a surface profile.

Variables in plastic media blasting. The PMB process if fast, economical, and safe. Although it resembles sandblasting, plastic media blasting doesn’t use hard abrasives, such as silica sand. Instead, it uses recyclable plastic particles that range in hardness from 3 (calcite) to 4 (fluorite) on the Mohs scale. Hard abrasives are around 7 (vitreous pure silica) on the Mohs scale.

The plastic media are pneumatically applied in a range between 200 and 400 pounds (depending on nozzle size) per hour at pressures of 20 to 40 pounds per square inch. Nozzle-to-part distance is typically 1/2 to 1 1/2 feet. In contrast, the media used in sandblasting are conveyed at volumes of 1,000 pounds per hour and pressures normally at 100 pounds per square inch or more. Nozzle-to-part distance is typically 3 to 4 feet.

Sandblasting removes most coatings and a portion of the substrate to produce an anchor pattern or white metal finish before priming or powder coating. Often, sandblasting causes substantial damage to thin metal or sensitive substrates. On the other hand, plastic media blasting can be used to remove coatings without damaging substrates.

When using plastic media blasting, certain variables for the application will be considered, including: blasting pressure, blast nozzle angle to substrate, media flow rates, media dwell time, nozzle size, nozzle-to-part distance, coating type, substrate type and thickness, blast-media type and size, media contamination control including part pre-cleaning, consistent grit size distribution (media replenishment), masking requirements, and blasting equipment.

The technical expertise necessary to make decisions about the variables involved in plastic media blasting comes from experience and hours of testing. Consequently, much of the initial success or failure in this technology is determined by how much support you receive from equipment and media suppliers.

Equipment for plastic media blasting. In actual practice, the preceding variables aren’t constantly and separately considered during the stripping process. Normally, the PMB operator, who ahs had proper training and experience, has predetermined the parameters for a given substrate. However, state-of-the-art equipment is available to apply the plastic media.

For example, electric remote controls at the blast nozzle adjust blasting air pressure and media flow to accommodate the rapid transition from one substrate to another. This feature is invaluable for stripping expensive, complex parts and allows the operator to go from steel to aluminum to fiberglass (on automobiles) or from magnesium to titanium to clad or anodized aluminum to advanced composites (on aircraft airframes).

The original PMB systems were little more than sandblast pressure vessels, modified with 60-degree cone bottoms to accommodate the flow characteristics of the plastic blast edia. The relcaim systems for the media were typically the same type used for steel-shot reclaiming. Although they had tremendous recovery capability, thty lacked the capability to properly clean the low density plastic media.

Some of today’s PMB systems offer features not even considered a few years ago. Media reclaim systems on some machines now use true cyclone separators with low-horsepower fans and motors. As a result, they efficiently remove all coating residue and plastic fines from the plastic media. This permits the recovery and reuse of the media, often for up to to 30 cycles or more, which results in media use rates as low as 9 pounds per blast hour.

Large-are magnetic separators for teh removal of ferrite particle contamination are also available now. Moreover, several plastic blast media systems now offer dust collectors with reverse pulse-jet cleaning systems for the removal of even submicron particles from the dust collector exhaust air. Some PMB systems now provide nozzle-mounted, quartz halogen blast lamps to increase lighting of the part, which is crucial when working on sensitive substrates.

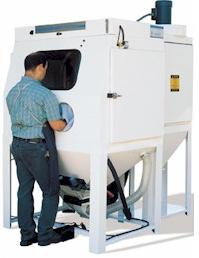

Advanced plastic media blasting cabinets (glove boxes) are available with operator controls to rapidly adjust blast air pressure and media flow to accommodate senstive substrates. Conversion kits are available to retrofit existing open-blasting PMB systems and PMB blast cabinets with operator remote controls for adjusting blast air pressure and media flow.

Low-cost plastic media blast rooms are now made of 18-gauge sheet metal, rather than the 10- to 12- gauge steel plate typical of sandblasting booths. Because PMB doesn’t remove metal, these economical rooms are satisfactory for a variety of applications.

Advanced and highly efficient dust collectors that provide ventilation for blast rooms are also available now.

Some compact, energy-efficient, modular systems provide automatic reverse pulse-jet cleaning on demand, with each module having a capacity of 6,000 to 16,000 cubic feet per minute. High-density particle separation (HDPS) systems are available to remove heavy particles, such as silica sand, from otehrwise recylcable plastic media. Although this isn’t a major concern for many stripping applications, military and aerospace manufacturers are very conscious of the damage that can occur by this type of contamination. under current military specifications, media having a contamination level of 0.02 percent b weight (200 parts per million) must be taken out of service until they can be effectively cleaned. Airframe manufacturers require that the plastic media be free of contaminants to within 0.03 percent. The low-profile HDPS equipment available today as on- or off-line systems exceed the requirements of the US military and airframe manufacturers.

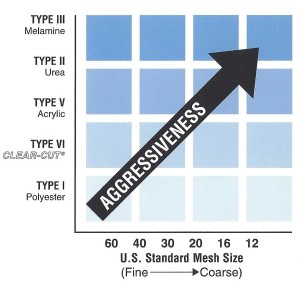

Media types for plastic media blasting. The plastic media industry has changed tremendously in recent years. When the US military began using PMB, it authorized only three types of plastic media, all thermosets: Type I, Polyster; Type II, Urea formaldehyde; and Type III, Melamine formaldehyde. by May 1988, the US Navy had approved two more media types per MIL -P-85891 (AS): Type IV, phenol formaldehype, a thermoset; and Type V, Acrylic, a thermoplastic. In March 199, the Navy drafted a new specification, adding a sixth media type per MIL-P-85891-0386DD: Type VI, poly allyl diglycol carbonate, a thermoset.

Because one media type won’t work for all coating and substrate combinations, selecting the right plastic media for your application is critical to successful PMB.

This chart provides a guide to selecting media candidates. (Type IV is not listed because it is not commonly used, and has many of the characteristics of Type II, however, it breaks down faster.)

Type I. Polyester is the softest plastic media type and is used only of the most delicate substrates.

Type VI. Poly allyl diglyocol carbonate is significantly more aggressive on coatings than Type I, but is very safe on most substrates. It has good removal rates when used on composites in particular. In the past, a composite part with an unacceptable coating wasa scrapped because there wasn’t a safe way to remove the coating. for that reason, a removal rate of only 1/2 square foot per minute is considered economical because it saves the expensive part. Removal rates of more that 1 square foot per minute aren’t unusual, especially with coatings that are less than 5 mils thick.

Type V. Acrylic has proved to be the most popular plastic media for thin aluminum parts. It is less aggressive and has lower removal rates than Type II. Although it won’t remove many primers, it is very long-lasting and can be a good choice if you only want to remove the topcoat.

Type II. Urea formaldehyde is the most heavily used plastic media, accounting for more than 50 percent of today’s media use. It’s used on a variety of soft metals, some composites, and steel. Powder coatings usually come off easily with this plastic media type.

Type III. Melamine is the hardest and most agressive plastic media type. Extremely tenacious powder coatings applied to hard metals respond to this media type.

It is important to consider both media type and grit size. With an increas in grit size , the action on the coating and substrate is more aggressive (see above chart).

Cost of plastic media blasting. The costs of plastic media blasting per blast hour can fluctuate, depending on a variety of factors, including labor costs, media costs, energy use, overhead, waste disposal, removal rate, media reclamation efficiency. Operating costs are typically in the range of $45-$65 per blast hour, or from 20 cents to $2.15 per square foot. Typically, the cost does not exceed 50 cents per square foot.

No one coating removal method is best for all applications. For this reason we offer extensive consulting and assistance with product selection.