Composition Materials supplies blast media for stripping paints, removing primers, enamels, powder coating, rust & scale from steel, foundry metals, aluminum, bronze, plastics, composites, rubber, wood, brick and stone. Abrasives also available for Deflashing, Tumbling and Deburring applications. Below are a selection of Hard Abrasives for use in profiling metal surfaces with an anchor finish in preparation for paint & coatings, as well as in peening applications. Also, available, Soft Abrasives – Plastic Media, Walnut Shells & Corn Cob.

For technical support, product selection and ordering, call (800) 262-7763.

• Very hard & aggressive blast media

• Used on steel and hard metals

• High toughness & hardness

• Non-skid abrasives

• 99.4% ultra-pure abrasive

• Very hard blast media

• For blasting & non-skid

• Cosmetic microdermabrasion

• Hard, aggressive abrasive blast media

• Blast cleaning, stripping paint & scale

• Etching & profiling hard metals

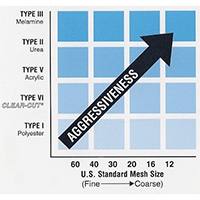

• Available in 4 grades of hardness

• Abrasive blasting & stripping media

• Peening, cleaning & surface prep

• Available in 4 grades of hardness

• Re-usable up to hundreds of times

• Hardest abrasive blast media

• Tough media with very sharp edges

• Glass etching & stone engraving

• Excellent replacement for sand

• Glass bead blast cleaning

• Polishing, peening, deburring

• For shiny & polished finishing

• Silica-free & lead-free

• Environmentally safe, non-toxic

• Low-cost method of paint stripping

• Mil-Spec approved: MIL-P-85891A

• Coatings removal & surface cleaning

• Eco-friendly crushed shell grit

• Walnut shell sandblasting, blast cleaning

• Steel, buildings, bridges, boats

• Deflashing media

This article provides an overview of abrasive blasting, media types and abrasive blasting equipment. Comparisons between hard and soft abrasives are given, as well as the dangers of sandblasting, and effective replacements to sand.