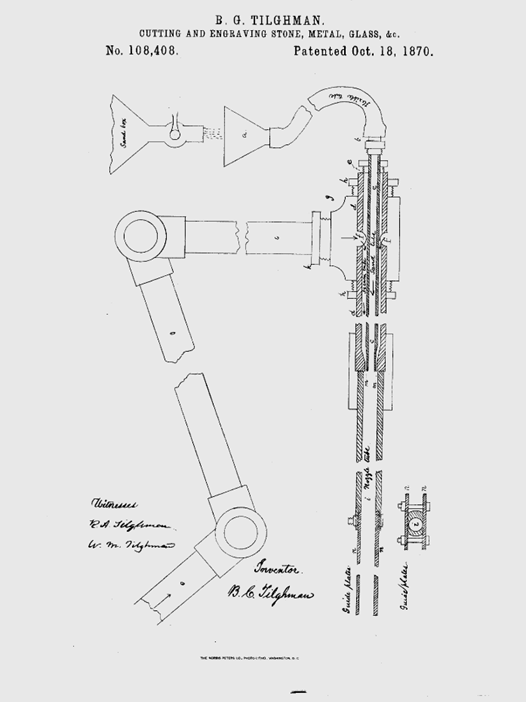

The history of Plastic Sandblasting, or Plastic Media Blasting, dates to 1870 when a patent (pictured below), was awarded for a process using silica sand and compressed air to clean surfaces. Sandblasting was the most common coatings removal method until just after WWII when chemical paint strippers quickly became popularized and offered an alternative to sandblasting, which carried silicosis health risks.

In 1947, DuPont received a patent for using synthetic resins to blast clean aluminum and magnesium aircraft engine parts. Then, in 1981, the U.S. Navy put out an RFP for less hazardous paint stripping methods, at which point Plastic Media Blasting was evaluated for use on blast cleaning helicopters and related components. The U.S. Air Force then followed suit, and in 1983 successfully tested the use of plastic media on the F-4 Phantom aircraft. These tests led to formal adoption of Plastic Media under military specification MIL-P-85891.

‘Sandblasting’ has become a general description of using various types of media for the removal of paint and coatings, surface cleaning, and surface preparation.

Plastic Sandblasting, or Plastic Media Blasting, has several advantages. For example, blasting with Plastic Media is not as aggressive as other media types (e.g. sand, aluminum oxide, steel shot and grit). Being less aggressive, Plastic Sandblasting offers efficient paint and coating removal without marring, pitting or warping substrates. Additionally, compared to chemical strippers, Plastic Media Blasting offers a non-toxic paint removal method.

Composition Materials has been manufacturing PLASTI-GRIT® Plastic Blast Media from recycled materials since 1987. Please contact us for more information on our custom-manufactured recycled plastic abrasives.